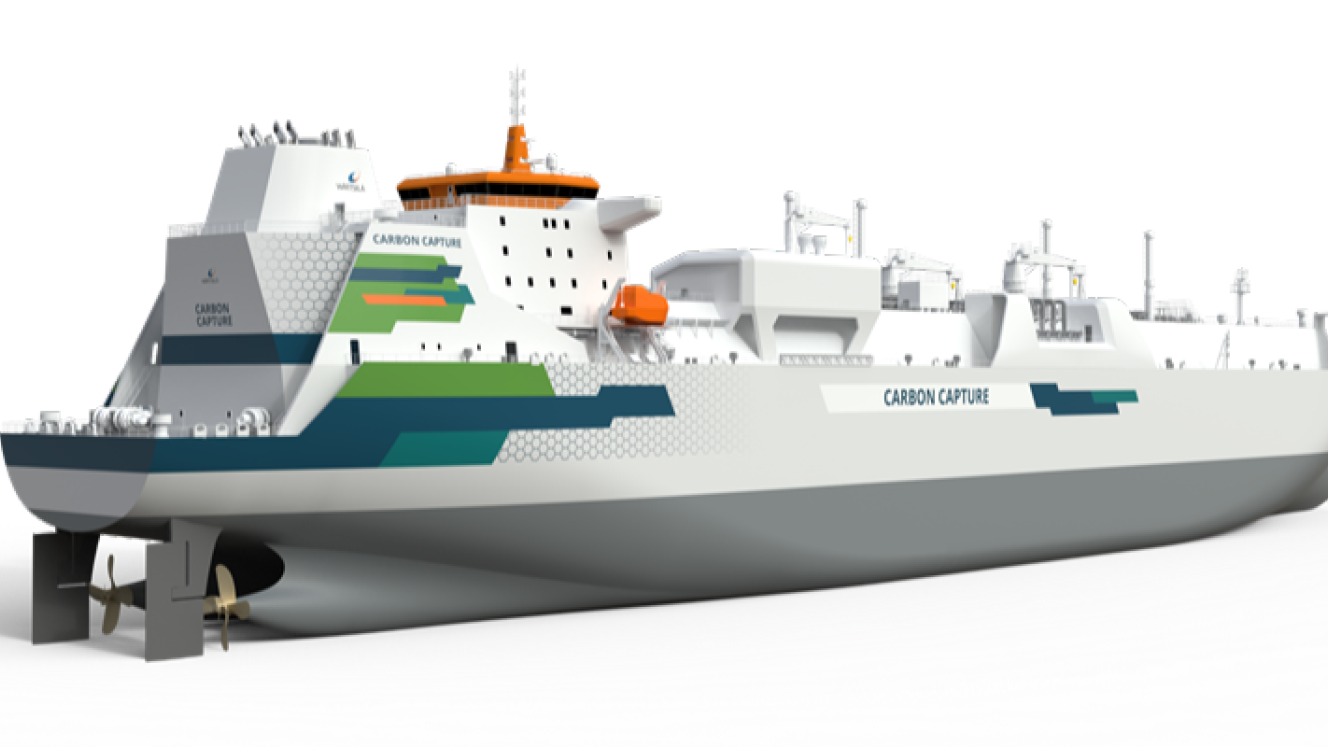

Technology group Wärtsilä’s carbon capture solution (CCS) has been commercially released to the global maritime industry after undergoing full-scale implementation tests.

According to Wärtsilä’s tests, the new carbon capture solution has been proved to reduce vessel CO₂ emissions by up to 70%, providing ship owners with an immediate solution to meet increasingly stringent environmental regulations.

The ability to capture CO₂ from ship exhaust systems will have a major impact on the industry’s efforts to reduce GHG emissions, taking into account the International Maritime Organization’s 2050 reduction target.

Wärtsilä President and CEO Håkan Agnevall said the solution was a game-changer for the maritime industry.

“We are already seeing huge interest in the market for this solution. Ahead of shipping’s net-zero targets, this new technology complements the industry’s ongoing efforts to dramatically reduce emissions from vessels and prevent stranded assets.”

The launch follows the successful installation of the world’s first comprehensive, full-scale solution aboard Solvang ASA’s vessel Clipper Eris, where the technology captures emissions from all exhaust gas sources.

Earlier this year, Wärtsilä installed its CCS technology on the 21 000 cubic metre ethylene carrier for full-scale testing and optimisation.

The solution, which has been in operation since the Clipper Eris set sail from Singapore in February, will support Solvang ASA’s commitment to reducing carbon emissions and promoting sustainable maritime operations.

Clipper Eris was already equipped with a broad range of Wärtsilä products, including exhaust scrubbers, making it an ideal candidate for the project.

Solvang has worked closely with Wärtsilä and other partners to ensure new-build vessels currently under construction were CCS-ready. This includes CCS-ready scrubber systems, as the engines will operate on HFO (heavy fuel oil), as well as necessary space reservation and utility requirements.

“While the shipping sector continues to explore options for lessening its environmental impact, CCS provides a significant shortcut for achieving meaningful sustainability,” said Edvin Endresen, CEO of Solvang ASA.

“Solvang has been at the forefront of advocating for, and adapting to, new technologies such as CCS for our deep-sea fleet. As one of the more promising solutions for marine decarbonisation, it was important for us to team up with an experienced and trusted partner such as Wärtsilä and we are excited at the potential its CCS offering will bring to our business.”

Wärtsilä has been developing the technology since 2019 and currently operates a research centre and test facility in Moss, Norway, capturing 10 tonnes of CO₂ per day from a Wärtsilä marine engine.

These tests, which are now supported by the full-scale installation onboard Clipper Eris, proved that the new CCS has the capability to reduce a vessel’s CO₂ emissions by up to 70%. Wärtsilä also estimates its CCS would have a carbon capture cost of €50-€70/mt CO₂ ($54-$76/mt CO₂), inclusive of capital and operating costs.

“Collaboration has been key here. To achieve this significant advance in maritime emissions control it is important to be able to cooperate with like-minded partners such as Solvang ASA. We congratulate them for their vision and support in bringing CCS to their fleet,” said Agnevall.

Wärtsilä’s CCS can be applied to the exhaust from any carbon-based fuel – such as HFO, methanol, liquefied natural gas and marine gas oil – and is designed to work alongside other emission-reduction technologies, including sulphur oxide scrubbers, nitrogen oxide reduction systems and particulate matter filters.